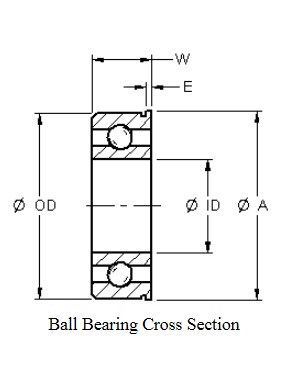

A ball bearing is a type of rolling-element bearing that uses balls to maintain the separation between the bearing races.

The purpose of a ball bearing is to reduce rotational friction and support radial and axial loads. It achieves this by using at least two races to contain the balls and transmit the loads through the balls. In most applications, one race is stationary and the other is attached to the rotating assembly (e.g., a hub or shaft). As one of the bearing races rotates it causes the balls to rotate as well. Because the balls are rolling they have a much lower coefficient of friction than if two flat surfaces were sliding against each other.

Ball bearings tend to have lower load capacity for their size than other kinds of rolling-element bearings due to the smaller contact area between the balls and races. However, they can tolerate some misalignment of the inner and outer races.

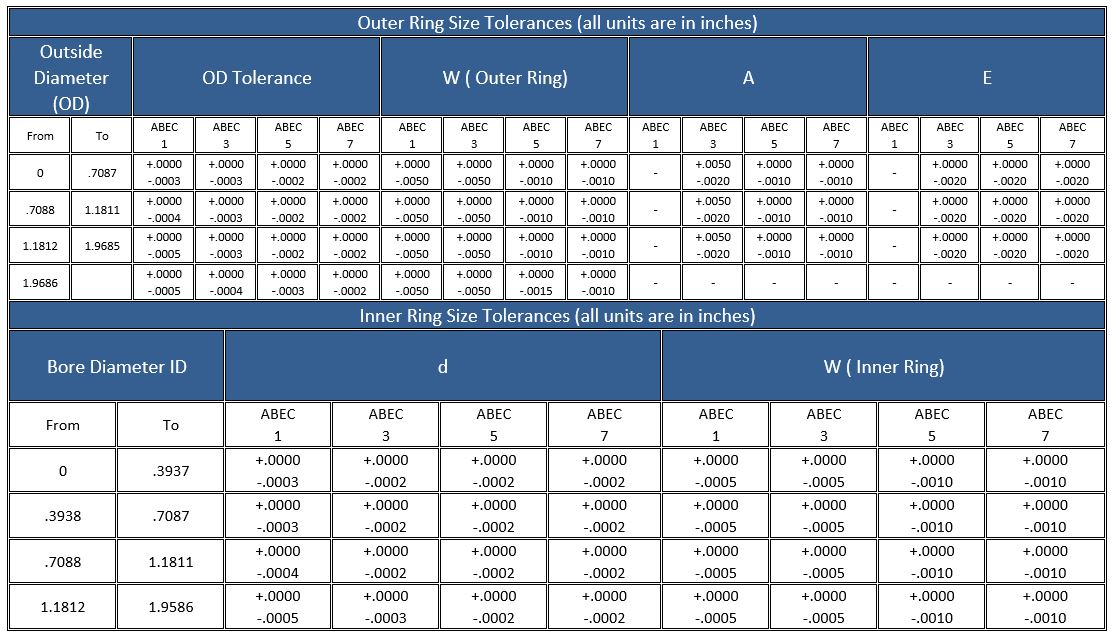

The following are Annular Bearing Engineers Committee (ABEC) for ball bearings quality classes. Applications should only require ABEC1 or ABEC3 ball bearings. When highly precise position in required, ABEC 5 or ABEC 7 ball bearings should be specified.

|

The ABEC scale is an industry accepted standard for the tolerances of a ball bearing. It was developed by the Annular Bearing Engineering Committee (ABEC) of the American Bearing Manufacturers Association (ABMA). There are five classes from largest to smallest tolerances: 1, 3, 5, 7, and 9. The higher ABEC classes provide better precision, efficiency, and greater speed capabilities, but do not necessarily make the components spin faster. The ABEC rating does not specify many other critical factors, such as smoothness of the rolling contact surfaces, ball precision or quality/type of steel used. The bearing material is not specified in the ABEC grades. Bearings not conforming to at least ABEC 1 can not be classified as precision bearings as their tolerances are too loose. The scale is designed to allow a user to make an informed decision about the type of bearing they are purchasing. High rated bearings are intended for precision applications like aircraft instruments or surgical equipment. Lower grades are intended for the vast majority of applications such as vehicles, mechanical hobbies, skates, skateboards, fishing reels and industrial machinery. High ABEC rated bearings allow optimal performance of critical applications requiring very high RPM and smooth operation. ISO’s equivalent standard is ISO 492. |

There are a number of factors covered by the ABEC grades. One is the eccentricity (roundness) of the track in the inner ring, which determines run-out. The references given below show the maximum eccentricity allowable.

ABEC 1: 0.0075 mm (0.000295”)

ABEC 3: 0.0050 mm (0.000197”)

ABEC 5: 0.0035 mm (0.000138”)

ABEC 7: 0.0025 mm (0.000098”)

ABEC 9: 0.0012 mm (0.000047”)