The active parts of the bearing: rolling elements, raceways, cage, must always remain absolutely clean and well lubricated. Shielding and sealing serve to ensure the permanence of these two factors that are vital for the bearing life, by preventing contaminating agents from entering the bearing and by retaining the grease.

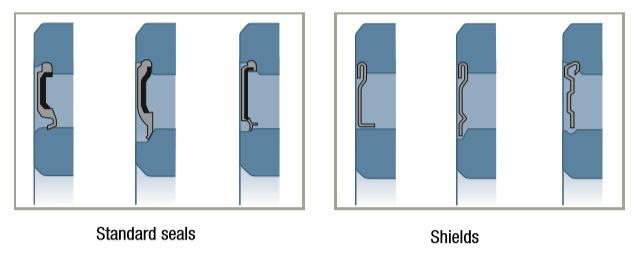

Two types of sealing devices are normally used with the bearings

Friction-free shields

These devices are based on the effect produced by a narrow space between rotating parts and fixed elements. These shielding devices produce virtually no friction and no wear. They are particularly suited to high speeds of rotation and high temperatures. Their efficiency can be reinforced by injecting grease into the bearing through the narrow gap between shield and inner ring.

Friction seals (contact)

The seal exerts pressure on the conjugate surface, usually by means of a lip. This prevents the ingress of impurities and moisture and/or loss of lubricant.

The pressure can be created: • either by the load exerted by a spring incorporated at the end of the seal, • or by the elasticity of the seal material and appropriate fitting of the lip on its contact surface.